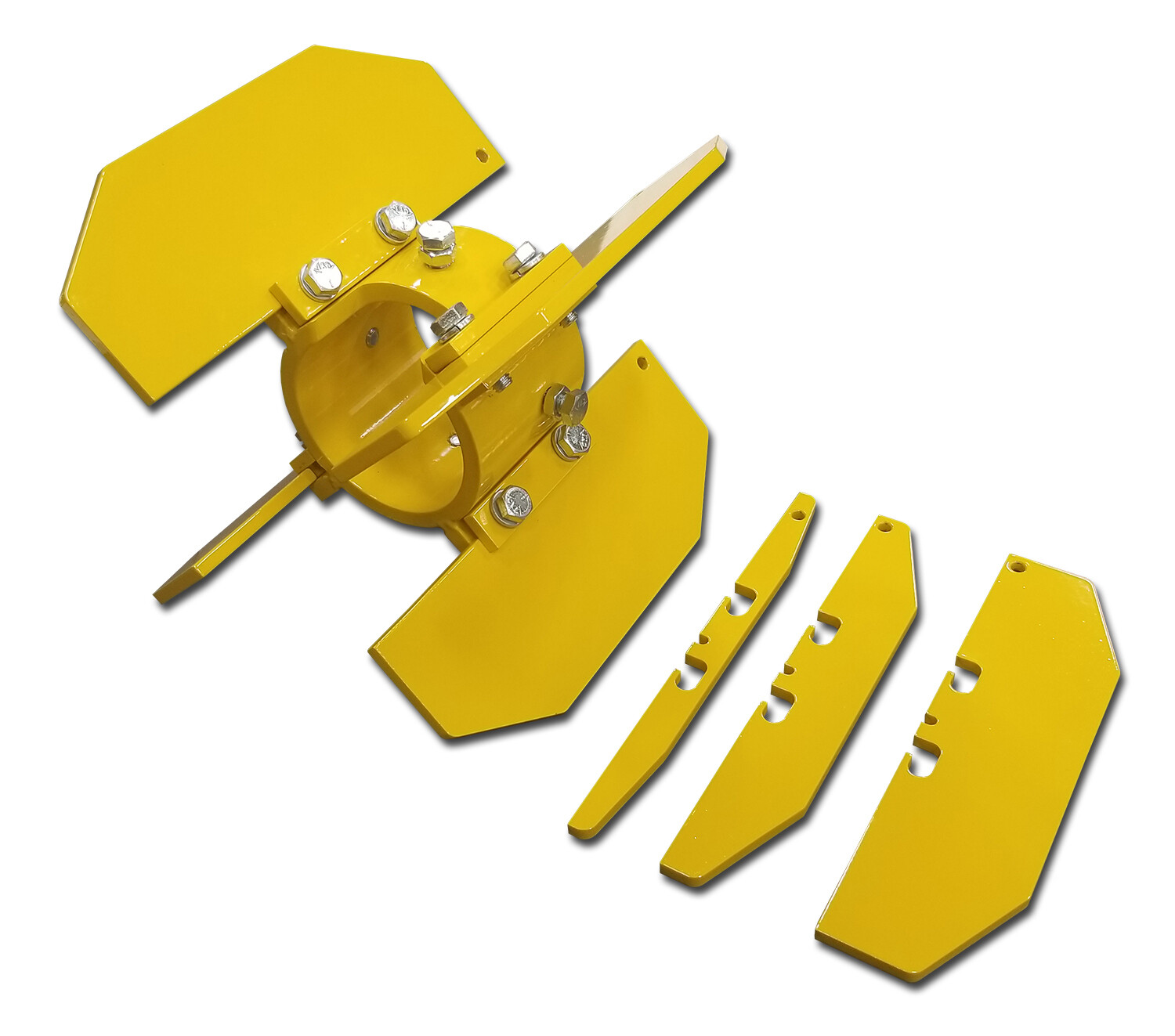

Speed Skid Collar & Skid Assemblies

*PATENT PENDING*

UEMSI/HTV’s all-new Speed Skid products were made specifically to work with all of the industry’s lateral and mainline flanged and round-bodied root cutter motors.

This uniquely engineered-and-manufactured root cutter collar and skid assembly will pay for itself in time-saving efficiency in changing from one size Speed Skid to another.

Speed Skids are manufactured with two ‘L’ shaped notches in the lower edge, allowing the Speed Skid runner to be easy dropped onto the compression bolts and pulled back. The operator then tightens the bolts, which draws the floating compression plate securely against the skid runner, sandwiching it between the motor plate and the floating compression plate.

This quick-change operation is accomplished by the use of one 1/2” box wrench, as the floating plate is threaded, eliminating the need for a nut to compliment the compression bolts; thus simplifying the skid-swap process. On a conventional root cutter system, the operator would have to remove each nut and bolt holding each skid- not so with the Speed Skid.

The lateral Speed Skid root cutter system can be used on ALL 2 3/8” diameter root cutter motors, while the mainline Speed Skid root cutter system can be used on all round mainline root cutter motors such as the Patriot style as well as the UEMSI/HTV grey hydraulic flange-style root cutter motors, which are also seen in the industry as generic blue or black.

| UEMSI/HTV P/N |

Description |

| GLRCS-KIT | Lateral Speed Skid Collar and Skid Assembly (4”, 6”, 8” and 10”) |

| GRCS-KIT | Mainline Speed Skid Collar and Skid Assembly (6”, 8”, 10” and 12”) |

Call us today for pricing and availability - (877) 389-9999.